Introduction

Special Purpose Machines SPM are custom-engineered systems designed to perform specific industrial tasks with high precision, efficiency, and repeatability. Unlike general-purpose machines, SPM are tailored to meet unique operational requirements—whether it’s drilling, welding, assembling, or inspection. In addition to it as industries across Europe, North America, and Asia accelerate their adoption of smart manufacturing and automation, the design of SPM has become a critical engineering discipline.

Basically from automotive production in Germany to medical device assembly in the U.S. and electronics manufacturing in Southeast Asia, SPMs are the backbone of high-throughput, low-variation operations. This guide certainly explores the essential design principles that ensure these machines deliver performance, reliability, and compliance across global markets.

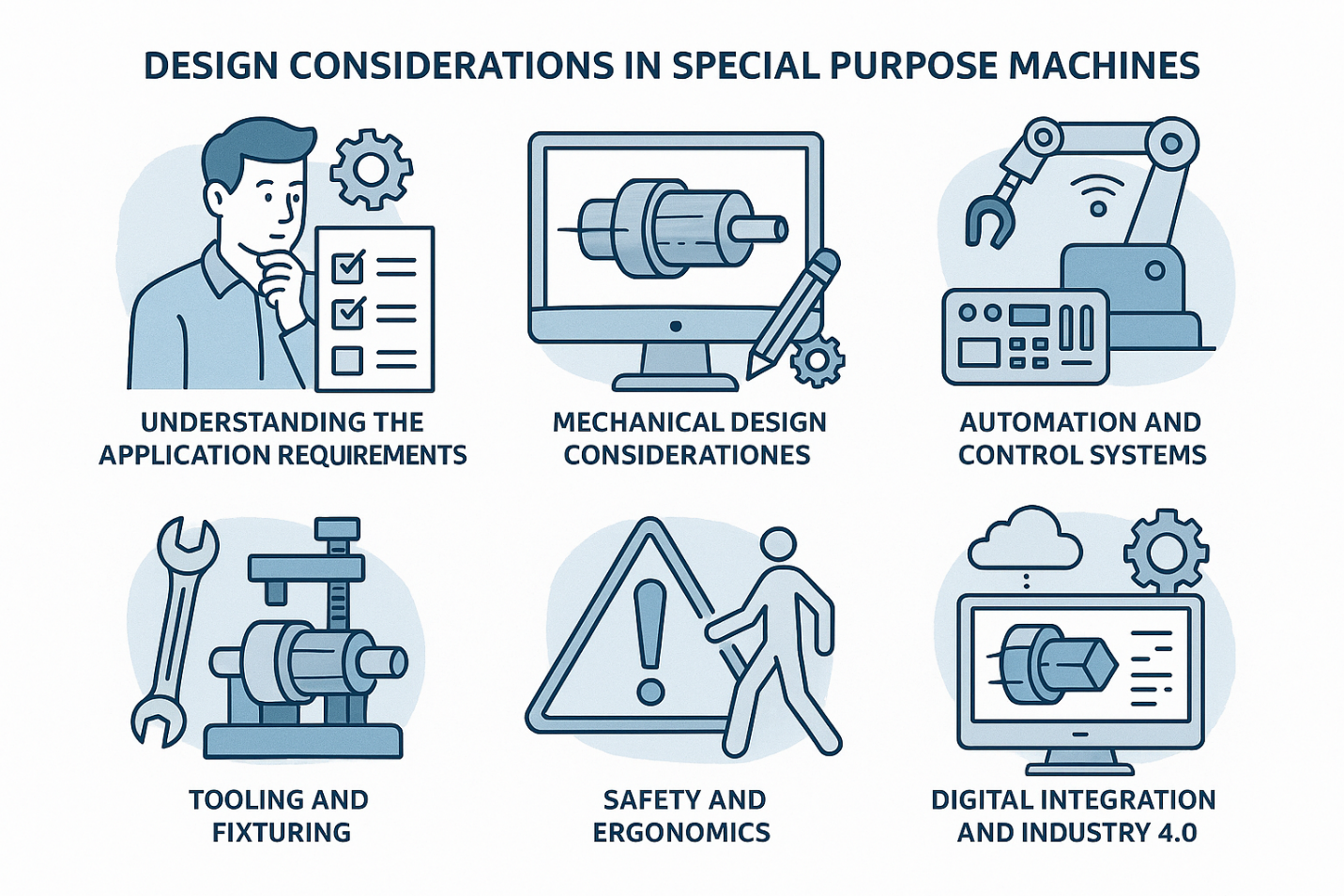

1. Understanding the Application Requirements

Every successful SPM begins with a clearly defined use case:

- Process Analysis: This Include sequence of operations, cycle time, and additionally quality expectations.

- Product Characteristics: It Defined by all in all Dimensions, tolerances, material properties

- Production Volume: Determines both the automation level and machine robustness

- Industry Norms: IATF 16949 (automotive), ISO 13485 (medical), AS9100 (aerospace)

- Regulatory Compliance: CE marking (EU), ANSI/UL (USA), RoHS, REACH

A well-articulated functional specification ensures the machine aligns with production KPIs and delivers as well as business value across regions.

2. Mechanical Design Considerations

Basically mechanical design in SPM must balance precision, durability, and manufacturability:

- Structural Integrity: It is mostly provided by FEA for rigidity and vibration damping

- Material Selection: Selection can be done based on load, wear resistance, and environment altogether.

- Kinematics & Ergonomics: Smooth motion profiles and operator-friendly interfaces

However in the world some regions emphasize sustainable engineering and eco-friendly materials and some prioritize lean design, compact automation, and cost-efficiency.

3. Modularity and Standardization

While SPM are custom-built, modular design offers flexibility and scalability:

- Shorter Time-to-Market

- Simplified Maintenance and Upgrades

- Global Sourcing: Standard components from Festo, SMC, Bosch-Rexroth, Schneider Electric, etc.

Hence using ISO-standard mechanical interfaces and EN ISO 12100-compliant modules ensures interoperability and safety across plants.

4. Automation and Control Systems

Besides modern SPM integrate advanced control technologies:

- PLC & HMI Integration: For example Siemens TIA Portal, Allen-Bradley Studio 5000

- Sensor Networks: Particularly Diagnostics, feedback and predictive maintenance

- Motion Control: Servo systems, stepper motors and linear actuators.

- Smart Connectivity: OPC UA, MQTT, Modbus TCP

However the SPM compliance Essentials are:

- CE Marking (Europe)

- UL Certification (USA)

- CCC Compliance (China)

5.Tooling and Fixturing

Indeed tooling in SPM is central to performance and adaptability:

- Quick-Change Tooling: It enhances not only flexibility but reduces downtime also.

- Precision Fixtures: Ensures Both the repeatability and reduce operator dependency.

- Wear Management: Mostly Coatings and hardening techniques used to extend tool life.

- Vision-Guided Systems: Overall ABB, KUKA, Fanuc, Yaskawa gives dynamic part orientation

Henceforth tooling standardization and global supply chain optimization are key to scalable deployment of a SPM.

6.Safety and Ergonomics

At first Safety is engineered into every aspect of SPM design:

- Risk Assessment: Generally ISO 12100, ANSI B11, OSHA 1910.147 ae the risk assesment standards

- Guarding & Interlocks: Mechanical and electronic safeguards i.e. Guarding and safety curtains.

- Ergonomic Design: ISO 6385 principles provided that operator comfort and accessibility

- HMI Standards: Multilingual touchscreens, intuitive interfaces

So far detailed documentation and validation, functional safety and operator liability, rapid adoption of global safety frameworks are the worldwide nuances.

7.Digital Integration and Industry 4.0

SPM (Special Purpose Machines) are now integral to smart factory ecosystems:

- IoT Connectivity: Remote monitoring and analytics

- Digital Twins: Simulate machine behavior for optimization

- Cloud Integration: Centralized control and reporting

- Edge Computing: Real-time diagnostics and predictive maintenance

Presently leapfrogging into smart automation, focusing on cybersecurity, interoperability, and IIoT are the global trends in the considerations of SPM.

8.Reliability, Maintainability, and Lifecycle Support

Overall (SPM) Machine uptime directly impacts profitability:

- High MTBF Design

- Condition-Based Maintenance: Vibration, temperature, and pressure sensors

- Accessible Maintenance Zones

- Standardized Protocols: ISO 14224 for reliability engineering

Hence Reducing Total Cost of Ownership (TCO) is a top priority for global manufacturers.

9.Cost vs. Capability Trade-Offs

Design engineers must balance performance of a SPM with cost-efficiency so that:

- Capital Investment vs. Operational Savings

- Local vs. Imported Components

- Automation Level: Manual assist, semi-automated, fully autonomous

- Energy Efficiency: ISO 14001 compliance, carbon neutrality goals

Simulation tools like SolidWorks, Siemens NX, and Autodesk Inventor support smarter decisions during the design phase of the SPM.

10.Testing, Validation, and Global Commissioning

Robust validation ensures machines (SPM) meet real-world expectations:

- FAT (Factory Acceptance Test)

- SAT (Site Acceptance Test)

- GAMP 5 Validation: For life sciences and pharma

- Documentation: Risk assessments, schematics, maintenance plans

Global commissioning of a SPM may involve remote diagnostics, virtual support, and cloud-based monitoring especially in post-pandemic operations.

*Conclusion: Designing for a Borderless Manufacturing World*

Overall Designing Special Purpose Machines i.e. SPM is a multidisciplinary challenge where mechanical design, automation, ergonomics, and digital intelligence converge. Whether serving Tier-1 suppliers in Germany, medical manufacturers in the U.S., or electronics producers in Southeast Asia, SPM must deliver:

- Customization with reliability

- Compliance with global standards

- Smart integration with factory ecosystems

- Long-term value across diverse markets

By embracing a holistic, globally aware design approach, engineers can create SPM that not only meet technical specifications but also empower manufacturers to scale efficiently, safely, and sustainably anywhere in the world.

Very good content. thank you

[…] you can refer our blog for SPM design. […]